Shop the Earth's Best Clays!

Choose from thousands of glazes!

Search pottery and forming tools!

Find yourt throwing equipment!

1

/

of

4

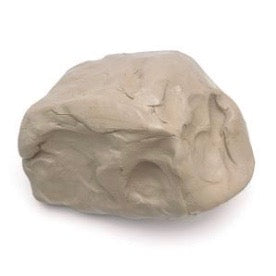

Popular Clays

-

Speckled Brownstone Cone 4-6

Regular price $0.94 USDRegular priceUnit price / per$0.00 USDSale price $0.94 USD -

Helios Porcelain Cone 7-11

Regular price $1.44 USDRegular priceUnit price / per$0.00 USDSale price $1.44 USD -

Bella's Blend Cone 04-6

Regular price $0.94 USDRegular priceUnit price / per$0.00 USDSale price $0.94 USD -

Little Loafer's Cone 5-6

Regular price $1.00 USDRegular priceUnit price / per$0.00 USDSale price $1.00 USD -

Earthen Red Cone 06-5

Regular price $0.94 USDRegular priceUnit price / per$0.00 USDSale price $0.94 USD -

Buncombe White Cone 3-6

Regular price $0.94 USDRegular priceUnit price / per$0.00 USDSale price $0.94 USD -

Phoenix Cone 7-10

Regular price $0.94 USDRegular priceUnit price / per$0.00 USDSale price $0.94 USD -

Raku Cone 06-6

Regular price $0.94 USDRegular priceUnit price / per$0.00 USDSale price $0.94 USD

1

/

of

8

Which clay is right for you?

It can be overwhelming to choose from the 30-plus types of wet clays we carry. First, find the firing range in cones you plan to fire your work.

- Low-Fire is around cone 06 to 02

- Mid-Fire is around cone 5 to 6

- High-Fire is around cone 7 and above

Search for the clays in the above drop-down Menu within that range - Earthenware (lower), Mid-Fire, or High-Fire.

Then choose a color, white/light or darker.

New Arrivals

-

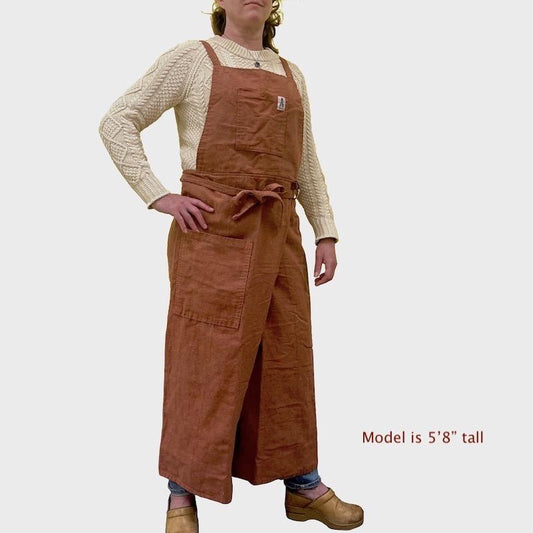

The Walking Apron Dyed

Regular price $65.00 USDRegular priceUnit price / per$0.00 USDSale price $65.00 USD -

RL-040 Wild Flowers

Regular price $16.95 USDRegular priceUnit price / per$0.00 USDSale price $16.95 USD -

Call to Backorder

Call to BackorderRL-041 Monstera

Regular price $16.95 USDRegular priceUnit price / per$0.00 USDSale price $16.95 USDCall to Backorder -

The Walking Apron Un-Dyed

Regular price $55.00 USDRegular priceUnit price / per$0.00 USDSale price $55.00 USD -

Call to Backorder

Call to BackorderRL-042 Prarie Flowers

Regular price $16.95 USDRegular priceUnit price / per$0.00 USDSale price $16.95 USDCall to Backorder -

RL-043 Mushrooms

Regular price $16.95 USDRegular priceUnit price / per$0.00 USDSale price $16.95 USD -

Call to Backorder

Call to BackorderBHR-150 Evergreen Forest

Regular price $19.95 USDRegular priceUnit price / per$0.00 USDSale price $19.95 USDCall to Backorder -

BHR-151 Flamingos

Regular price $19.95 USDRegular priceUnit price / per$0.00 USDSale price $19.95 USD -

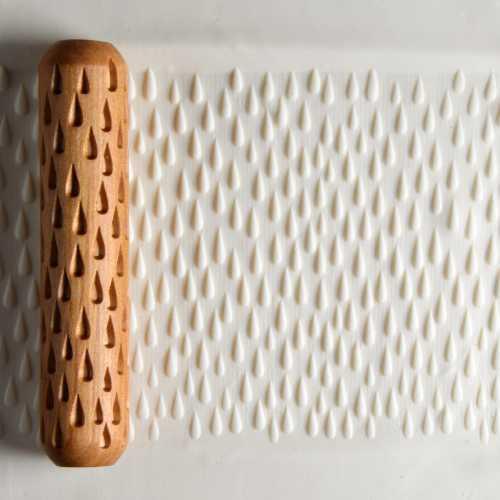

BHR-152 Rain

Regular price $19.95 USDRegular priceUnit price / per$0.00 USDSale price $19.95 USD -

BHR-132 Mod Drops

Regular price $19.95 USDRegular priceUnit price / per$0.00 USDSale price $19.95 USD -

BHR-140 Running Horses

Regular price $19.95 USDRegular priceUnit price / per$0.00 USDSale price $19.95 USD -

BHR-141 Waves

Regular price $19.95 USDRegular priceUnit price / per$0.00 USDSale price $19.95 USD -

BHR-143 Layered Lines

Regular price $19.95 USDRegular priceUnit price / per$0.00 USDSale price $19.95 USD -

Call to Backorder

Call to BackorderBHR-145 Hibiscus Flowers

Regular price $19.95 USDRegular priceUnit price / per$0.00 USDSale price $19.95 USDCall to Backorder -

BHR-146 Citrus Slices

Regular price $19.95 USDRegular priceUnit price / per$0.00 USDSale price $19.95 USD -

BHR-147 Coneflower

Regular price $19.95 USDRegular priceUnit price / per$0.00 USDSale price $19.95 USD

Tools and Equipment

CoreLite Shelves

CoreLite Shelves are made of a high thermal shock resistant material based...

Glazing Tools

Tools to help you apply or make your own glazes: glaze applicators,...

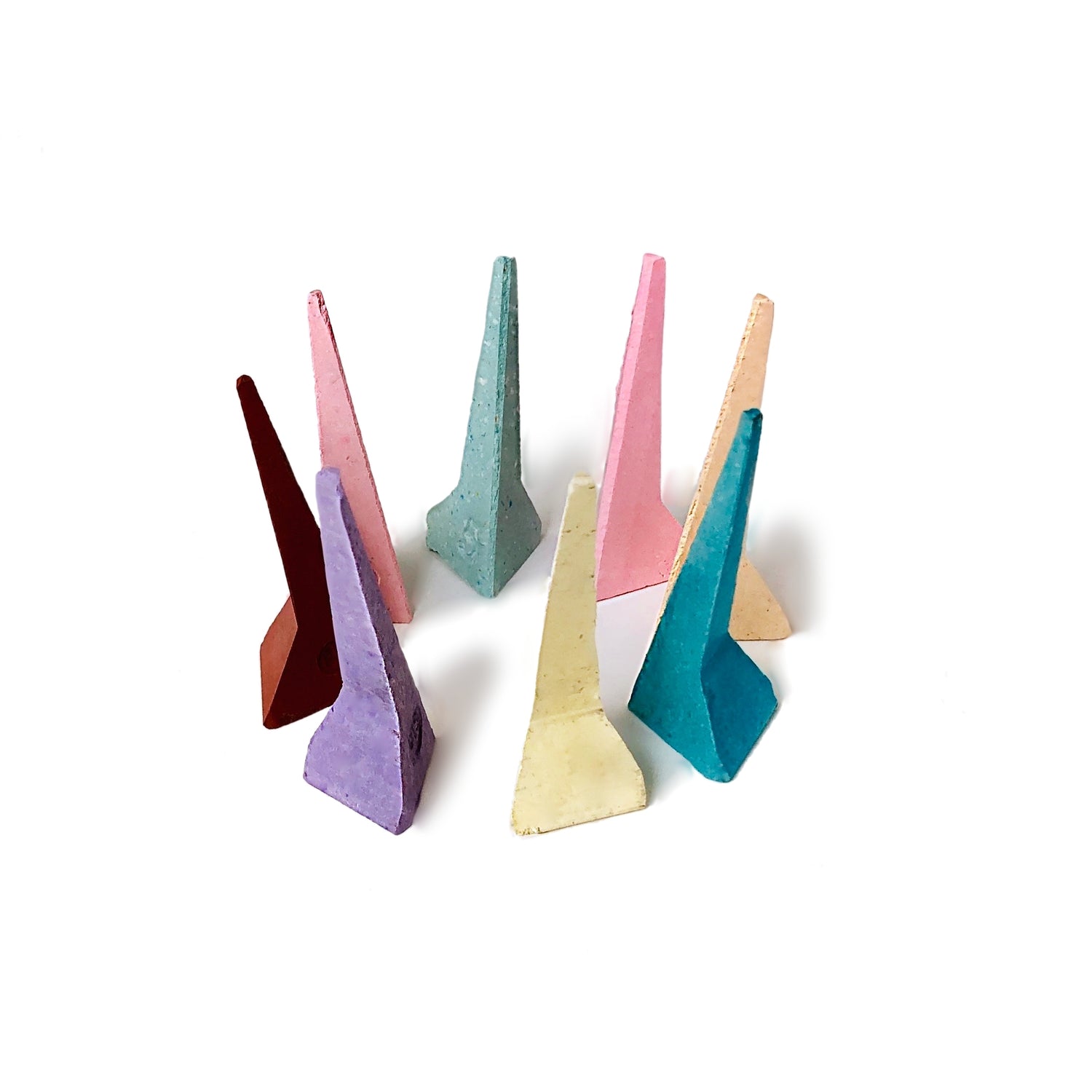

Self-Supporting Cones

Pyrometric Cones are used as witness cones to monitor ceramic firing in...

Showcase

-

Cup

Ursula

-

Container

Jason Walker

-

Cup with Handle

Emily Reason

1

/

of

3